Details

LTB-120 LABELING ON THE TOP AND BOTTOM

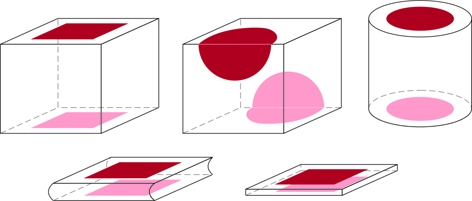

This machine is designed for top or bottom labelling on the flat containers. The LTB-120 comes with 150 mm wide belt conveyor and is ideal for manufacturers which are packing the food, cosmetic, personal care, nutraceutical, electronic.

Features:

- Stepping Motor for fast and accurate labeling perf ormance;

- Controlled by Microprocessor, LED display;

- Labels Counting feature / Production Run Counter;

- Label sensor for Paper or Opaque labels;

- Main structure of machine is made b y anodize aluminium that CNC processing;

- Height and angle are adjustable;

- In Line Application or Independent Operation;

- Modular design for easy maintenance / Quick and easy Changeo ver;

- Heavy Duty Construction;

- Capacity: up to 120 containers per minute.

Options:

- Inkjet printer;

- Transparent Label Sensor;

- Hot stamping coding machine;

- Angled-Label Module;

- Barcode Printer;

- Passive Top pressing Roll;

- Auto-Feeding Machine;

- Conveyor speed adjustment possibilities.

! Special features are subject to change without notice and/or depend on t he customer.

Additional Information

| Producer | PRINTMARK |

|---|---|

| Label length | 10 - 250 mm |

| Label width | 10 - 120 mm |

| Labeling speed | 7 - 30 m/min |

| Product diameter | - |

| Product wight | - |

| Conveyor width | Top conveyor: 80 mm, 150 mm (standard) |

| Conveyor length | 1200 mm (standard), Top conveyor: 500 mm |

| Conveyor speed | - |

| Max. labels roll diameter | 300 mm |

| Outside label roll diameter | 76 mm |

| Features | Labeling accuracy ±1 mm |

| Optional | Inkjet printer, Transparent Label Sensor, Hot stamping coding machine, Angled-Label Module, Barcode Printer, Passive Top pressing Roll, Auto-Feeding Machine, Conveyor speed adjustment possibilities. |

| Power Consumption | 230V 50Hz |

| Power | - |

| Dimensions | 1200 × 825 × 1500 mm |